For the fifth part in our series of short communist responses to common questions about China, we respond to questions such as “Isn’t China full of sweatshops? Aren’t Chinese workers basically like slaves making clothes and iPhones for Western consumers?”

As always, we encourage readers to reformat these answers for use across platforms. If you’ve designed pamphlets or infographics using these materials, please send them to us (e-mail: chuangcn@riseup.net) so that we can archive them here and repost on social media!

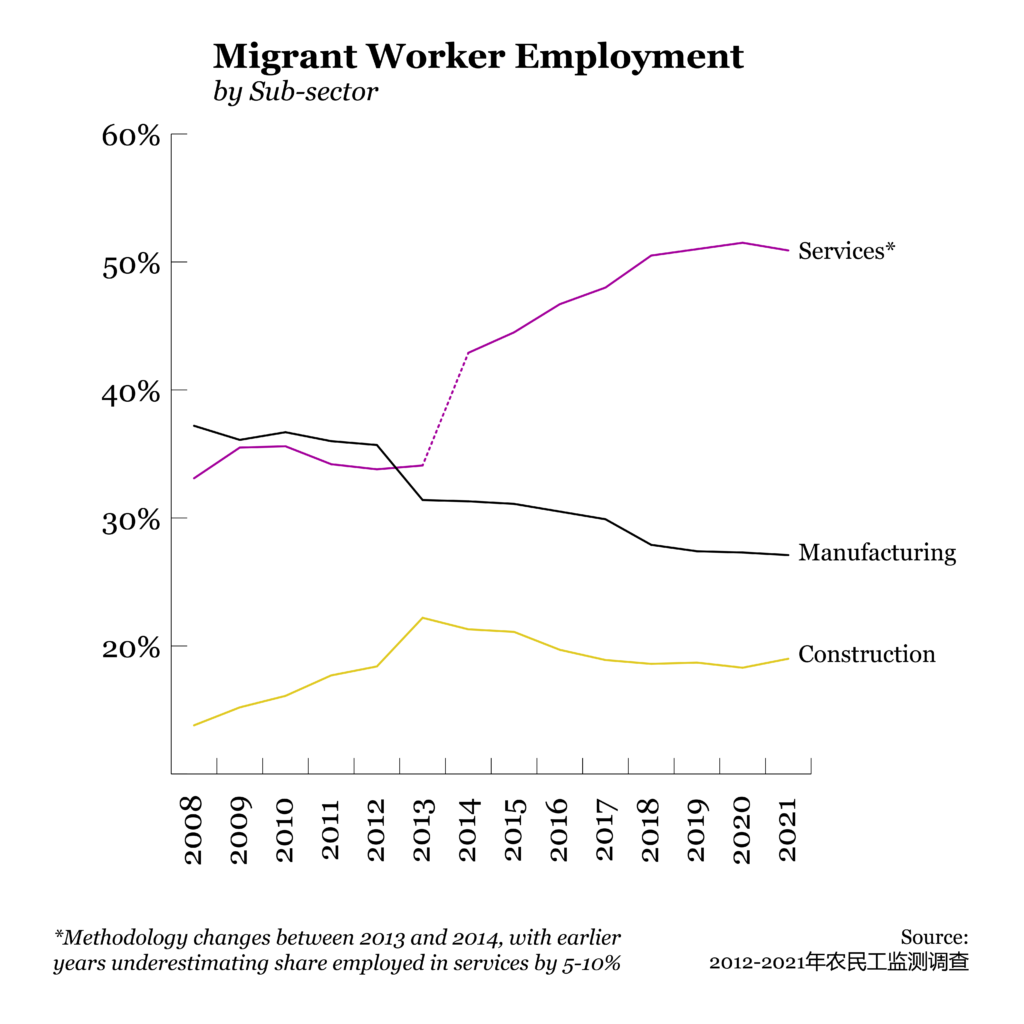

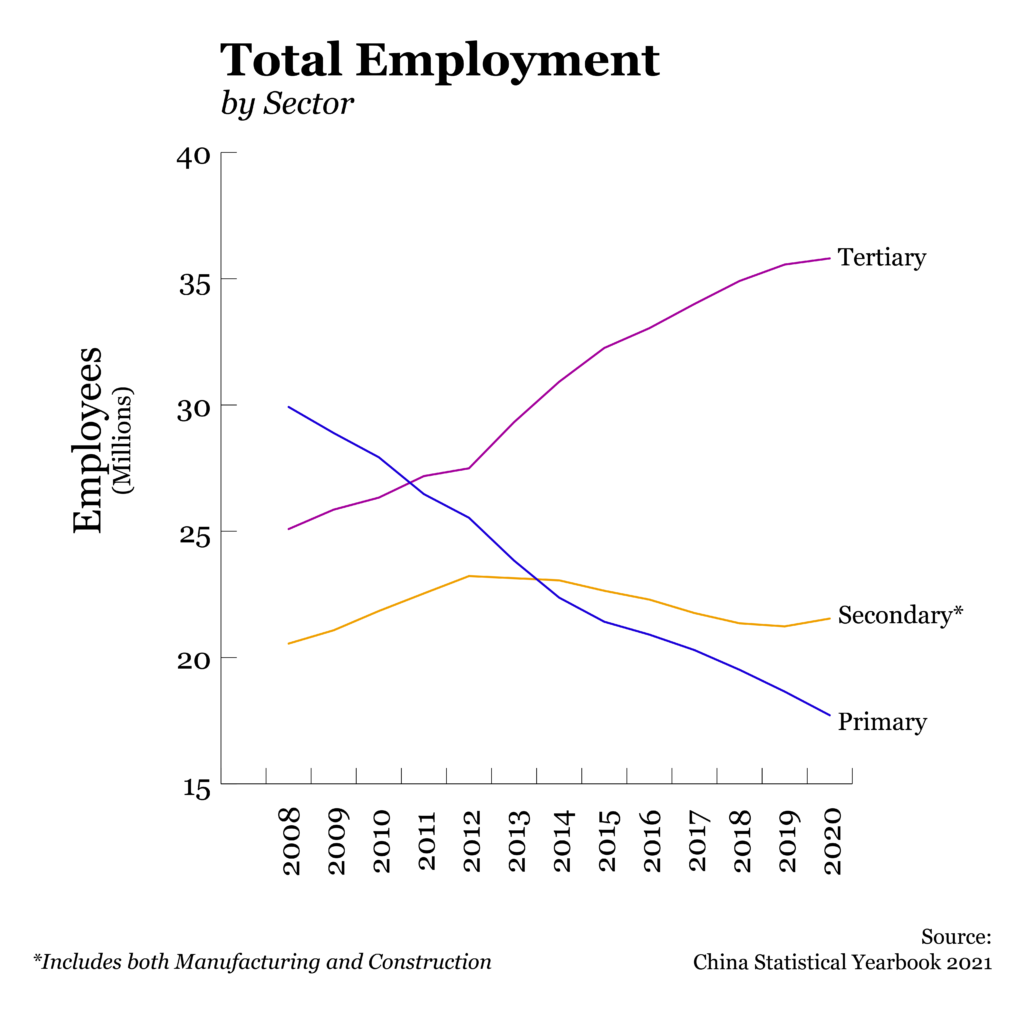

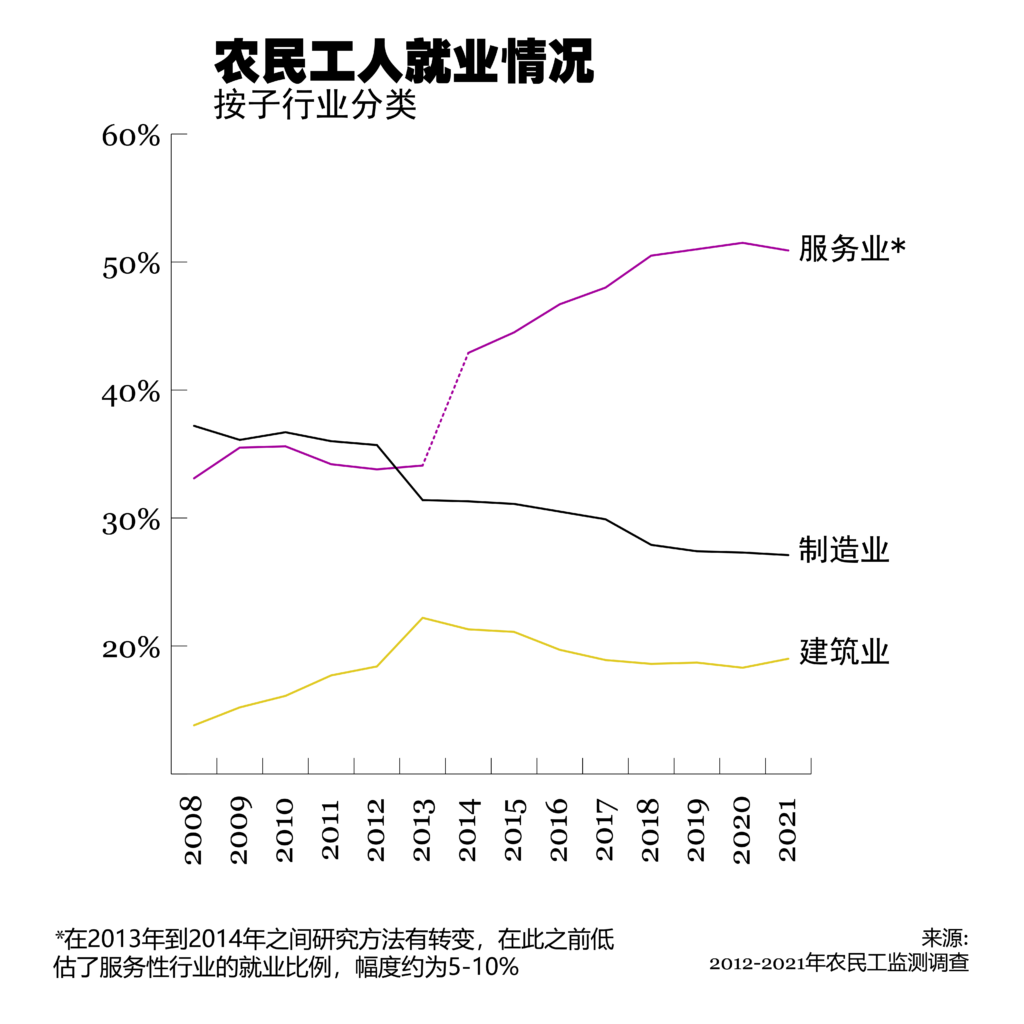

As with any other country, there are certainly factories with sweatshop conditions in China. But the motorcycle delivery driver and the burned-out office worker are more representative of Chinese employment today than a migrant worker on an assembly line making shoes or electronics for export. Sweatshop work is rightly abhorred for deplorable conditions, low pay, and long hours, but these features aren’t unique to factory work, nor is manufacturing the major site of worker resistance in China. Manufacturing played a bigger role in China’s economy a decade or two ago, in terms of employment and output. This is the period that most of our images of Chinese “sweatshops” come from, since it was the time when much of the world’s most labor-intensive manufacturing work was concentrated in the country. Today, however, Chinese manufacturing has grown more automated, and many of the most labor-intensive occupations are being relocated to poorer countries (for example: textile factories moving to Cambodia and Bangladesh, or low-end electronics assembly to Vietnam), meaning that industry continues to be a major source of economic output for China (as it is for all “postindustrial” countries) even as the country “deindustrializes” in the sense that a smaller share of overall employment is involved in manufacturing. This is a general pattern in capitalist development, reproduced again and again in different times and places.

But if this is something that has happened in other countries before, then why do we tend to associate images of sweatshop manufacturing with China? The first and most obvious reason is simply because a lot of the world’s low-end manufactured goods were, for about twenty years, “made in China.” This is beginning to change (just take a look at the tags on your clothing, likely made somewhere else) and it’s likely that we’ll begin to associate these images more with South and Southeast Asia in the near future, just as it was once common to associate the same images with tags reading “made in Mexico” or “made in Taiwan.” On the other hand, there is a second important reason that this image is so salient: The idea that Chinese workers are “iSlaves” dying to make your iPhone is also the result of years of propaganda by the NGO industrial complex, designed primarily to guilt consumers in the US or Germany and to shame Apple and its suppliers into more “ethical” production chains. The anti-sweatshop movement in the wealthy countries emerged as a poor substitute for organizing workers at the point of production, since offshoring had effectively undercut the power of existing unions. The ultimate impact of the movement on labor conditions has been negligible. Instead, it has mostly served as a way to recruit idealistic college students into institutional politics via non-profit activism.

There’s no ambiguity about the brutal labor practices that still prevail in the electronics assembly sector, which still employs millions of workers in China. The iPhone production chain became a topic of attention, in part, because there was a spate of worker suicides at the Shenzhen production plant where the phones were produced. But the reality is that work kills, in every country, and across many industries. The construction industry is far more deadly than manufacturing, and simply by reading Chinese news one can find reports of parcel or food delivery worker deaths at least once a month in recent years.[1] The image of the Chinese sweatshop entered the imagination of people in the wealthy countries because it was a convenient target for consumer politics campaigns. These campaigns are common in rich countries because they play on people’s “first world” guilt, invoke orientalist fantasies about a brainwashed or helpless Asian populace, and are also relatively toothless—even helping to rebrand the monopoly corporations of the rich countries as “ethical” by comparison. But there is no substantial difference in the degree of enslavement between Chinese workers making iPhones, European warehouse workers at Amazon, and the immigrant workers in American meatpacking plants.

Many of those who believe China is full of sweatshops also tend to believe other outdated and inaccurate portrayals of China and its dynamics of class struggle. Some believe, for example, that workers in sweatshops, or factory workers in general, are the leading class fraction of China’s proletariat (or even that “proletariat” = factory workers), and that developing a “labor movement,” rooted in this fraction, is the key to any progressive or revolutionary change. This view is common among a wide range of people inside and outside China, from enthusiastic left-wing activists to academics studying labor relations, or NGOs like China Labor Bulletin. For decades, they expected that factory strikes in the Pearl River Delta might turn into a wave of unionization, enable collective bargaining with employers, or even produce independent left-wing labor parties. But these things never came to pass and the “labor movement” in China died before it was born. In reality, there is no single “leading fraction” of the working class as a whole or within China. The basic idea here is chauvinistic, rejecting the struggles of certain proletarians in favor of “proper” struggles that fit a pre-determined ideological schema that bears little relationship to reality. The labor movement perspective has always obscured the full spectrum of the real, changing cadence of class struggle in China. Reliable and comprehensive data on social protests can be hard to come by, but we have done our best to illustrate what we do know in our articles “No Way Forward, No Way Back” and “Picking Quarrels,” in issues 1 and 2 of the Chuang journal (2016 and 2019).

More careful analysis of the actual data shows that not only is the employment structure of China shifting away from labor-intensive factory work toward a more nebulous array of services and higher-tech production, but also that protests and social struggles are shifting away from the patterns of the 2000s and early 2010s, which had been defined by rural protests against state appropriation of land and labor struggles in the cities. Labor actions in manufacturing have fallen precipitously as a portion of all labor actions, according to Wickedonna data and other records of labor struggles such as China Labor Bulletin. At the same time, other forms of social unrest, like protests over housing by more affluent social strata, are growing, and have often outnumbered labor disputes in recent years. Meanwhile, the forms taken by class struggle have diversified. The introduction of flexible employment contracts and various forms of “gig” labor have worsened precarity and intensified working hours across a wide range of sectors, bringing new issues to the forefront of struggles.

As we state in our summary of these dynamics in “Picking Quarrels”:

Rather than coalescing under an affirmative “worker” identity, subjectivities of a different kind are forming in relation to the present structure of the Chinese economy. A communist prospect, if possible at all, must be collectively constructed, rather than imported from insular activist or academic circles. Moreover, it must stretch across deeply fractured segments of the proletariat despite their conflicting interests, and today seems unable to rely on a single, hegemonic subject said to represent the interests of the class as a whole, as the mass industrial worker did (briefly and with questionable results) for the labor movement of old. If this communist horizon arrives, it will almost certainly take on a form initially alien to our expectations, adapting pre-existing identities in unpredictable and even unpalatable ways.

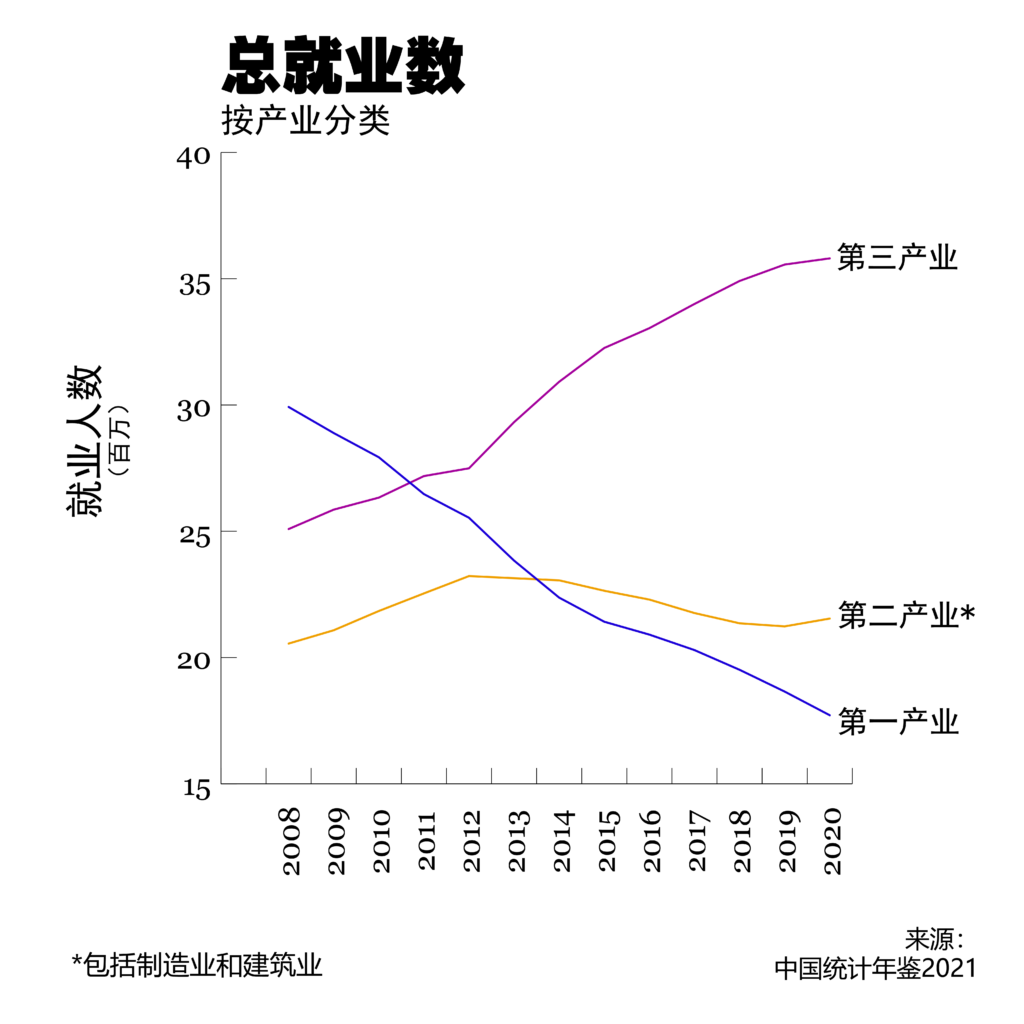

These trends in unrest are also a reflection of changes in China’s job structure, which in the near future is going to look more and more like those of “more developed,” “postindustrial” countries—many of which are still major producers of the world’s industrial goods, even though they are no longer major employers of the world’s industrial workers. Shit jobs in the service industry already dominate the economy, and employment is becoming increasingly precarious and low-paid, amid rising costs. China’s job structure is becoming more dependent on the service sector and moving away from agriculture, mining, manufacturing and construction. As in wealthier countries, the labor market in major Chinese cities is also bifurcating, with a majority of residents employed in lower-paying, lower-skill services and logistics work, and a minority employed in higher-paying, higher-skill jobs.

This doesn’t mean that everything about our image of the “sweatshop” is wrong. Ideas about Chinese sweatshops have their roots in the real economic developments of the 1990s and 2000s. Jobs in the manufacturing sector grew dramatically in the years after China joined the World Trade Organization in 2001. Foreign manufacturers poured into coastal regions, drawing people out of the agricultural sector and into manufacturing, alongside industries like construction. Many of the first major labor strikes and protests in the manufacturing sector were indeed against sweatshop conditions such as unsanitary canteen food, low wages, and military style management. The worst conditions were found in the most labor-intensive sectors such as textiles. Again, though: none of this was unique to China. Similar sweatshops had operated (and often continue to operate) in earlier garment production hubs, even within the wealthy countries. Over the course of the 2000s, however, the phasing out of the “Multi Fibre Arrangement” (MFA), which had mandated quotas that limited the amount of garment exports to wealthy countries, ultimately saw garment production even more heavily concentrated, with China winning out over most other competitors. This confluence of factors ensured that Chinese industrial zones would become the face of “sweatshop” labor for much of the world.

But after a decade of mass migration into coastal production zones, labor costs began to rise. When this happens, employers are faced with two choices: technological upgrading to increase productivity, or relocation to sources of cheaper labor. Both of these trends began to accelerate in China over the course of the 2010s. The expansion of manufacturing jobs peaked in the first years of the decade and has since declined (both in terms of the total number of workers in the sector and as a share of total employment). This was matched by a smaller decline in manufacturing’s share of total economic output: From 2010 to 2019, the sector’s contribution to GDP dropped from 31.61% to 27.17%. At the same time, many of the more labor-intensive industries, with stereotypically “sweatshop” conditions, either moved out of China or deeper into the Chinese interior where labor and land are cheaper, environmental regulations more lax, and local governments more willing to subsidize industrial capital. Other industries took a different route, making expensive technological upgrades and shedding workers as they entered into more high-end production lines. For a more comprehensive illustration of the industrial development of China in the late 20th and early 21st centuries, see our data briefs: “The Changing Geography of Chinese Industry,” and “Measuring the Profitability of Chinese Industry.”

These very broad statistics understate just how dramatically the structures have changed for working people in China, and how far employment has moved away from “sweatshop” manufacturing toward precarious service jobs. According to the latest migrant worker surveys, jobs in manufacturing, while decreasing in number each year, have also seen both the highest pay compared to other sectors and the highest growth in pay rates. In contrast, the service sector, which now employs the most people, also has the lowest wages and the slowest rates of wage growth. Wages for migrant workers grew fastest in manufacturing, at a rate of 3.5 percent, while service sector jobs in sales or food service grew at 1.7 and 2.1 percent respectively.

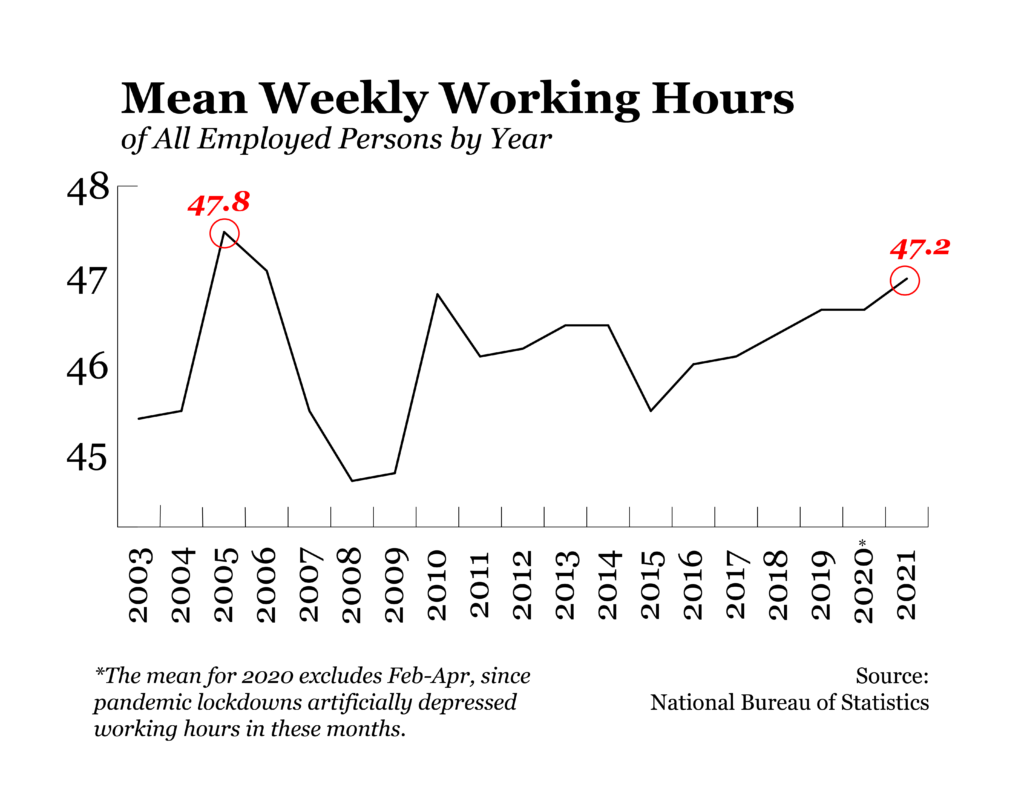

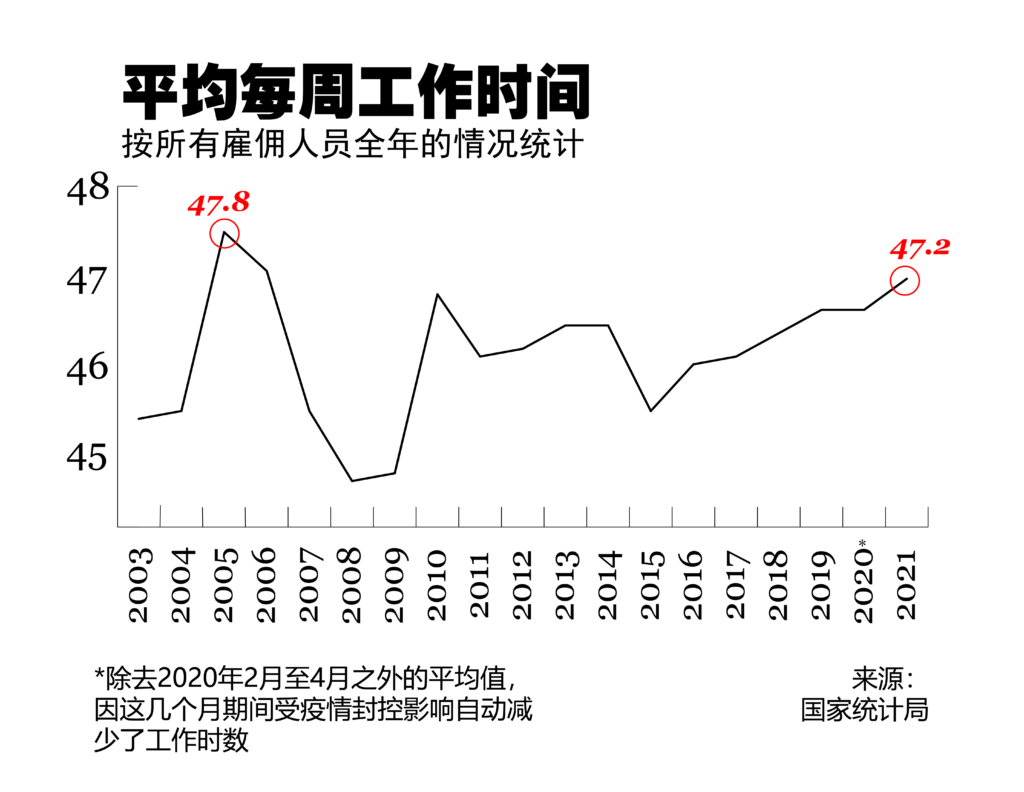

And in terms of labor time, of course stereotypes about sweatshop workers conjure up images of grueling hours performing monotonous tasks on assembly lines. While workers in manufacturing surely work long hours, those in service jobs work by far the longest, in a country where working hours are reaching unprecedented levels. And whereas it was common ten or twenty years ago for migrant workers in construction and manufacturing to die from exhaustion or overwork, nowadays it is more common to hear about such incidents occurring in the tech industries. The lengthening of the working day is one of the primary forces behind internet buzzwords like “lying flat” (tangping 躺平), or the “996” system where employers expect employees to work from 9am to 9pm six days a week.

China’s own National Bureau of Statistics data show a clear increase in working time over the years, according to surveys on average weekly working hours for all employed persons. The hours climbed steadily in the 2000s, in the years following China’s accession to the WTO, reaching an initial peak in 2005. They dipped during the global financial crisis and its immediate aftermath of 2008-2009, and then began climbing again, first gradually then more steeply in recent years. The bureau began releasing figures on a monthly basis in late 2019, which showed that weekly working hours hit their highest figure on record in October of 2021, when China’s economy had flown into overdrive during a brief surge. Other data tell a similar story and show that the slow and steady increase in labor hours has been developing for some time. The 2017 China Time Use Survey published a follow-up report on the nation’s first ever time-use study, performed by the National Bureau of Statistics in 2008. These findings showed that the proportion of workers doing overtime increased from 12 percent of the working population to 42 percent. The survey also showed that China has longer working hours than any other country with comparable data, with the exception of Colombia, and longer working hours than any OECD country, with the exception of Turkey.

In sum, China is not defined by sweatshops, nor are its proletarian struggles – in fact, its class composition and struggles are increasingly similar to those in other “more developed” countries. To understand this, we have to overcome many of the tropes portraying China as being fundamentally different, so we can together realize our common fate and better support one another in our common struggle.

[1] There are no detailed official statistics on worker deaths in logistics, or manufacturing for that matter. However, Chinese news reports regularly cover work related accidents, horrific injuries, and deaths. Projects like China Labour Bulletin’s Workplace Accident Map has records hundreds of major workplace accidents per year, involving worker deaths or multiple workers injured. In 2019, before the pandemic and under more “normal” conditions for delivery drivers, CLB recorded 15 delivery driver deaths.

难道中国不是世界血汗工厂吗? —— 常见中国问题解答系列

在我们共产主义对有关中国的常见问题的简短回应系列的第五部分中,我们回答诸如这些的问题:“中国不是到处都是血汗工厂吗?中国工人基本上不就是为西方消费者缝衣服、造iPhone的奴隶吗?”

和以往一样,我们鼓励读者用其他格式把这些回答转发到各个平台。如果您利用这些材料设计了小册子或者信息图表,请发送一份给我们(邮箱:chuangcn@riseup.net),这样我们就可以留个存档,并且在社交媒体转发!

与今天的任何其他国家一样,中国当然存在条件如血汗工厂的工作场所。但相比起流水线上生产供出口的鞋子或电子产品的农民工,电动车上的外卖骑手和疲惫不堪的上班族更能代表当今中国的就业情况。血汗工厂的工作因恶劣的条件、低工资和长时间的工作而受到憎恶理所应当,但这些特征并非工厂工作所独有,制造业也不是中国工人反抗的主要地点。依据就业和产出的情况而言,制造业在一二十年前在中国经济中发挥了更大的作用,而正是这个时期里形成了大部分我们对中国“血汗工厂”的印象,因为当时世界上大部分劳动密集型的制造业工作都集中在中国。然而,今天,中国制造业已经变得更加自动化,许多劳动密集型特征最强的工作岗位正在转移到更贫穷的国家(例如:纺织厂转移到柬埔寨和孟加拉国、低端电子组装生产线转移到越南等),这意味着即使中国正在“去工业化”(制造业占总就业的比例在减少),工业仍然是中国经济产出的主要来源(对于所有“后工业化”国家也是如此)。这是资本主义发展的一般形态,在不同的时代和地点被反复再生产。

但如果这个过程在其他国家已经发生过,那为什么我们会倾向于将血汗工厂制造业的形象与中国联系起来呢?第一个也是最明显的直观原因,不过是世界上许多低端制成品在大约二十年的时间里都是“中国制造”。这种情况开始发生变化(看看你衣服上的标签,很可能是别处制作的),在不久的将来,我们很可能会开始将血汗工厂这个印象更多地与南亚和东南亚联系起来,就像以前一样人们通常会将相同的印象与写着“墨西哥制造”或“台湾制造”的标签联系起来。另一方面,这个形象如此显著还有第二个重要原因:这种“中国工人作为“i奴隶”正在拼死命地制造着你的 iPhone”的印象,也是非政府组织工业联合体多年宣传的结果,主要对象是美国或德国心中有愧的消费者,同时让苹果及其供应商羞愧难当,不得不采用更“道德”的生产链。富裕国家的反血汗工厂运动成为在生产节点组织工人的拙劣替代品,因为离岸外包实际上削弱了现有工会的力量。该运动对劳动条件的最终影响微不足道。相反,它主要成为一种招募方式,怀有理想主义的大学生借此通过非营利行动主义进入体制内政治。

毫无疑问,在中国仍然雇用上百万工人的电子组装部门里,残酷的用工情况仍然盛行。 iPhone生产链成为关注的话题,部分原因是生产手机的深圳工厂发生了多起工人自杀事件。但现实是——工作会杀人,这在每个国家、在许多行业均是如此。建筑业的死亡率远高于制造业,并且单看中国新闻,近几年就能至少每月一次发现快递员或外卖骑手死亡的报道。[1]中国血汗工厂的形象进入了富裕国家人们的想象,因为它是消费者政治运动的一个方便的目标。这些运动在富裕国家很常见,因为它们利用了人们对“第一世界”的愧疚感,唤起了关于被洗脑或无助的亚洲民众的东方主义幻想,而且这些运动相对没胆量——甚至通过不同地方的用工情况对比,为富裕国家的垄断公司重塑“道德的”形象。但制造 iPhone 的中国工人、欧洲亚马逊的仓库工人和美国肉类加工厂的移民工人之间的奴役程度并没有实质性差异。

许多认为中国充斥着血汗工厂的人也倾向于相信其他对中国及其阶级斗争动态的过时和不准确的描述。例如,一些人认为,血汗工厂的工人,或者工厂工人总体,是中国无产阶级的领导阶级部分(甚至“无产阶级”=工厂工人),并且相信将植根于这个部分的“工人运动”发展起来,是任何进步或革命性变革的关键。这种观点在中国国内外的人群中广泛存在,从热情的左翼活动家到研究劳资关系的学者、到像中国劳工通讯这样的非政府组织。几十年来,他们预计珠三角的工厂罢工可能会转变成一个工会化浪潮,让与雇主进行集体谈判、甚至产生独立的左翼工党也成为可能。但这些一直没有发生,中国的“工人运动”未生先死。实际上,无论是在整个工人阶级中还是在中国内部,都没有单一的工人阶级“领导部分”。这里的基本思想是沙文主义的,拒绝某些无产者的斗争,支持那些契合了预定的、与现实几乎没有关系的意识形态框架的“正当”斗争。这种工人运动的视角总是掩盖了中国阶级斗争真实的、不断变化的节奏的全貌。关于社会抗议的可靠和全面的数据常常很难获得,但我们已尽最大努力在第 1 、 2 期Chuang 杂志(2016 年和 2019 年)的文章“前不能进,后无退路”和“寻衅滋事”中阐述我们所知。

对实际数据更仔细的分析表明,不仅中国的就业结构正在从劳动密集型工厂工作转向更无定型的服务业和高科技生产,而且抗议和社会斗争模式也正从2000 年代和 2010 年代初的农村抗议国家征用土地和城市的劳工斗争模式中发生转变。根据 Wickedonna 的数据和中国劳工通讯等平台对劳工斗争的记录,制造业的劳工行动在所有劳工行动中的占比断崖式下降。与此同时,其他形式的社会动荡正在增加,如较富裕社会阶层对住房的抗议,而且近年来数量往往超过劳资纠纷。同时,阶级斗争的形式也多样化了。引入灵活雇佣合同和各种“零工”劳动形式后,工作变得更不稳定,大量部门的工时变长,为斗争前线带来新的问题。

正如我们在“寻衅滋事”中对这些动态的总结中所述:

肯定性的“工人”身份并没有聚合不同的主体性,恰恰相反,另一种与当前中国经济结构相关的主体性正在形成。共产主义的前景,要是有可能实现的话,必须集体构建,而不是从孤立的活动家或学术圈子引进。此外,尽管无产阶级深刻分裂的部分之间存在利益冲突,但该前景必须跨越这些裂痕,而今天似乎无法再像大众产业工人在旧工人运动里所做的那样(过程简短且结果存疑),依赖一个所谓代表整个阶级的利益的单一霸权主体。如果这种共产主义前景到来,它几乎肯定会具备一种起初与我们预期迥异的形式,并且以不可预测甚至令人不快的方式改造先前存在的身份。

动荡的这些趋势也反映了中国岗位结构的变化,在不久的将来,中国的岗位结构将越来越像“更发达”、“后工业化”国家——其中许多仍是世界上主要的工业品生产国,尽管它们不再是世界产业工人的主要雇主。服务业的狗屁工作已经主导了经济,在成本上升的情况下,就业变得越来越不稳定和低薪。中国的岗位结构越来越依赖于服务业,并逐渐远离农业、采矿业、制造业和建筑业。与较富裕的国家一样,中国主要城市的劳动力市场也在分化,大部分居民从事低薪、低技能的服务和物流工作,少数人从事高薪、高技能的工作。

这并不意味着我们关于“血汗工厂”形象的一切都是错误的。关于中国血汗工厂的想法源于 1990 年代和 2000 年代的实际经济发展。在中国于 2001 年加入世界贸易组织后的几年里,制造业部门的工作岗位急剧增加。外国制造商涌入沿海地区,将人们从农业部门吸引到制造业以及建筑等行业。制造业部门的许多第一次大规模罢工和抗议确实是针对血汗工厂的条件,例如不卫生的食堂食品、低工资和军事式管理。最糟糕的情况出现在纺织业等劳动密集型程度最高的部门。不过,重申一遍:这一切都不是中国独有的。类似的血汗工厂曾在早期的服装生产中心运营(并且经常继续运营),甚至在富裕国家内也是如此。然而,在 2000 年代,随着强制配额,限制向富裕国家的服装出口量的“多种纤维协议”(MFA) 被逐步取消,服装生产最终更加集中,而中国成功超越大多数其他竞争对手。这些因素的结合确保了中国工业区将成为世界大部分地区“血汗工厂”劳动力的面貌。

但在人口大规模迁移到沿海生产区之后的十年后,劳动力成本开始上升。发生这种情况时,雇主面临两种选择:通过技术升级以提高生产率,或搬迁至廉价劳动力的产地。这两种趋势在 2010 年代都开始在中国加速发展。制造业工作岗位的扩张在这十年的头几年触顶峰,此后已开始下降(既包括制造业的工人总数,也包括制造业占总就业人数的比例)。同样,制造业在经济总产出中所占份额也有小幅下降:从 2010 年到 2019 年,该部门对 GDP 的贡献从 31.61% 下降到 27.17%。与此同时,许多具有刻板印象里“血汗工厂”条件的劳动密集型产业要么迁出了中国,要么深入中国中腹,那里的劳动力和土地更便宜,环境法规更宽松,地方政府更愿意补贴产业资本。其他产业采取了不同的路线,在进入更高端的生产线时进行了昂贵的技术升级和裁员。有关 20 世纪末和 21 世纪初中国产业发展的更全面说明,请参阅我们的数据简介:“中国工业的地理变迁”和“衡量中国工业的盈利能力”。

这些非常宽泛的统计数据显现不出中国劳动人口的结构发生变化有多惊人,从“血汗工厂”制造业转向不稳定的服务业工作的程度有多高。根据最新的农民工调查,制造业的就业人数虽然逐年减少,但与其他行业相比,薪酬和薪酬增长率都是最高。相比之下,目前就业人数最多的服务业的工资最低,工资增长速度也最慢。农民工的工资增长最快的是制造业,增长率为 3.5%,而服务业的销售岗位或食品服务岗位分别增长 1.7% 和 2.1%。

至于劳动时间,关于血汗工厂工人的刻板印象当然会让人联想到在流水线上执行单调任务的艰苦时间。虽然制造业工人的工作时间当然很长,但在一个工作时间达到前所未有水平的国家,服务业工人的工作时间是目前最长的。一二十年前,建筑业和制造业的农民工因劳累或过度劳累而死亡很常见,而如今,更多听说此类事件在科技行业更容易听说。延长工作日是“躺平”或“996”制度(雇主希望员工每周工作六天,从早上 9 点工作到晚上 9 点)等互联网流行语背后的主要推动力之一。

根据中国自己的国家统计局多项关于所有就业人员平均每周工时的调查,多年来工作时间明显上升。在 2000 年代,在中国加入世贸组织后的几年里,工作时数稳步攀升,并在 2005 年达到了初步峰值。在2008–

2009 年全球金融危机及其后续期间有所下降,然后又开始攀升,先是逐渐上升,近几年更为陡峭。该局于 2019 年底开始按月发布数据,显示每周工作时间在 2021 年 10 月创下历史最高记录,当时中国经济正处于在短暂的飙升期中过速运载。其他数据也讲述了类似的趋势,表明劳动时间缓慢而稳定的增长已经发展了一段时间。 2017 年“中国时间利用调查”为国家统计局2008 年首次进行的全国时间使用研究提供了后续报告。这些调查结果表明,加班工人占工作人口的比例从 12% 增加到 42%。调查还显示,中国的工作时间比哥伦比亚以外的任何其他有可比数据的国家都长,也比土耳其以外的任何经济合作与发展组织。

总之,中国不是由血汗工厂定义的,它的无产阶级斗争也不是——事实上,它的阶级构成和斗争与其他“更发达”国家越来越相似。要理解这一点,我们必须克服许多将中国描绘成根本不同的陈腔滥调,这样我们才能一起意识到我们共同的命运,并在我们的共同斗争中更好地相互支持。

[1] 没有关于物流或制造业工人死亡的详细官方统计数据。然而,中国的新闻报道经常报道与工作有关的事故、重大的伤害和死亡情况。中国劳工通讯的工作场所事故地图等项目每年记录数百起重大工作场所事故,每一起涉及工人死亡或多名工人受伤。 2019 年,在疫情前送货司机工作条件更“正常”的情况下,中国劳工通讯记录了 15 名送货骑手死亡。